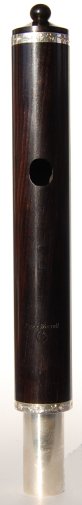

Thinned headjoint in African Blackwood

Standard headjoint in African blackwood

Peter Worrell Headjoints

The unique sound that only wood can deliver.

The rich dark fullness of a wooden flute provided with the addition of a wooden head.

Headjoints created for the individual to suit the physical shape of the embouchure.

The concept of tone is different for every player; therefore the headjoint offers the first point of reference for the artist.

Every headjoint is uniquely different, by the very nature of wood.

Peter Worrell offers two main designs.

The Thinned head

Maximum response, power and agility.Thinned to leave a raised lip plate.

Carved from a solid piece of wood.

Every embouchure is hand cut and finished.

The Solid head

A richness and depth of tone that only comes from wood.

Full wall thickness throughout.

Each headjoint is made from Grenadilla seasoned naturally for the minimum of 6 years.

Fittings are of silver with a solid wooden stopper.

Options

Headjoints also made from Kingwood, Cocobolo, Boxwood and Rosewood. Other woods on request.

Fittings available in gold on request.

Engraving by request.

Headjoint prices

Thinned head in african blackwood. Silver bands £1200.00

Solid head in african blackwood. Silver bands £1100.00

Contact Peter Worrell to order.

Care of your headjoint

Great

care must be taken with your wooden headjoint to prevent it from cracking.

Due to the difference in conditions it has to endure (hot/cold, wet/dry

etc) .

I recommend these simple procedures be carried out.

Breaking in a new head takes a while (3 to 6 months ).

Do not play for overly long periods until the wood has settled.

Warm the wood with your hands and blow air through the tube to slowly bring the wood up to room temperature before playing.

Always

swab out the head with a lint free cloth after playing.

Never return the head to the case if it has moisture in the bore.

When

the head is new the bore will need oiling. Thread a small piece of cloth

through your cleaning stick. Place a small amount of Raw Linseed Oil

or Almond Oil on the cloth and insert into the bore.

Do not apply too much oil. When you can see a slight sheen to all of

the

bore then you have applied the correct amount. Leave overnight. Swab

out any excess oil with a clean cloth.

This should be carried out at approximately 2 week intervals when the

head is new.

Continue every other month when the head is broken in.

Apply a light coat of oil to the external surface from time to time,

again removing the excess oil once a small amount has soaked into the

wood.